HYDRAULIC CYLINDER COMPONENT'S MANUFACTURING

After careful planning, it is time to start working the actual manufacturing process. The process starts with raw materials and their lathing process into ready-to-use components. At SOYSAL, we machine some of the components by ourselves at our factory. In the machining process, the raw material part is lathed into a right shape. Our highly experienced and skilled workers take care of the machining

HYDRAULIC CYLINDER ASSEMBLY

Before the assembly process starts, every part is carefully washed and protected. After all the pieces and components have been inspected and their cleanliness has been checked, the actual assembly process can start. First the seals are put in place (for piston, cylinder head etc) along with bearing and snap ring. The piston and cylinder head are attached to the rod. The seals are oiled around piston and cylinder head. After the rod is assembled with every component, the whole package is ready to be installed to tube. During every step of the way, the cleanliness is the top priority and at every point of the assembly, the surfaces are kept clean and properly wiped if necessary.The tube is inspected visually too – with light from inside as well – and after that the tube is attached horizontally to an installation bench, a bearing is installed and the tube is oiled properly from inside. The rod is carefully slid inside the tube with piston end first. The torque is set according to customer requirements. After the actual assembly of tube and rod is ready, the bearings and grease nipples are installed.

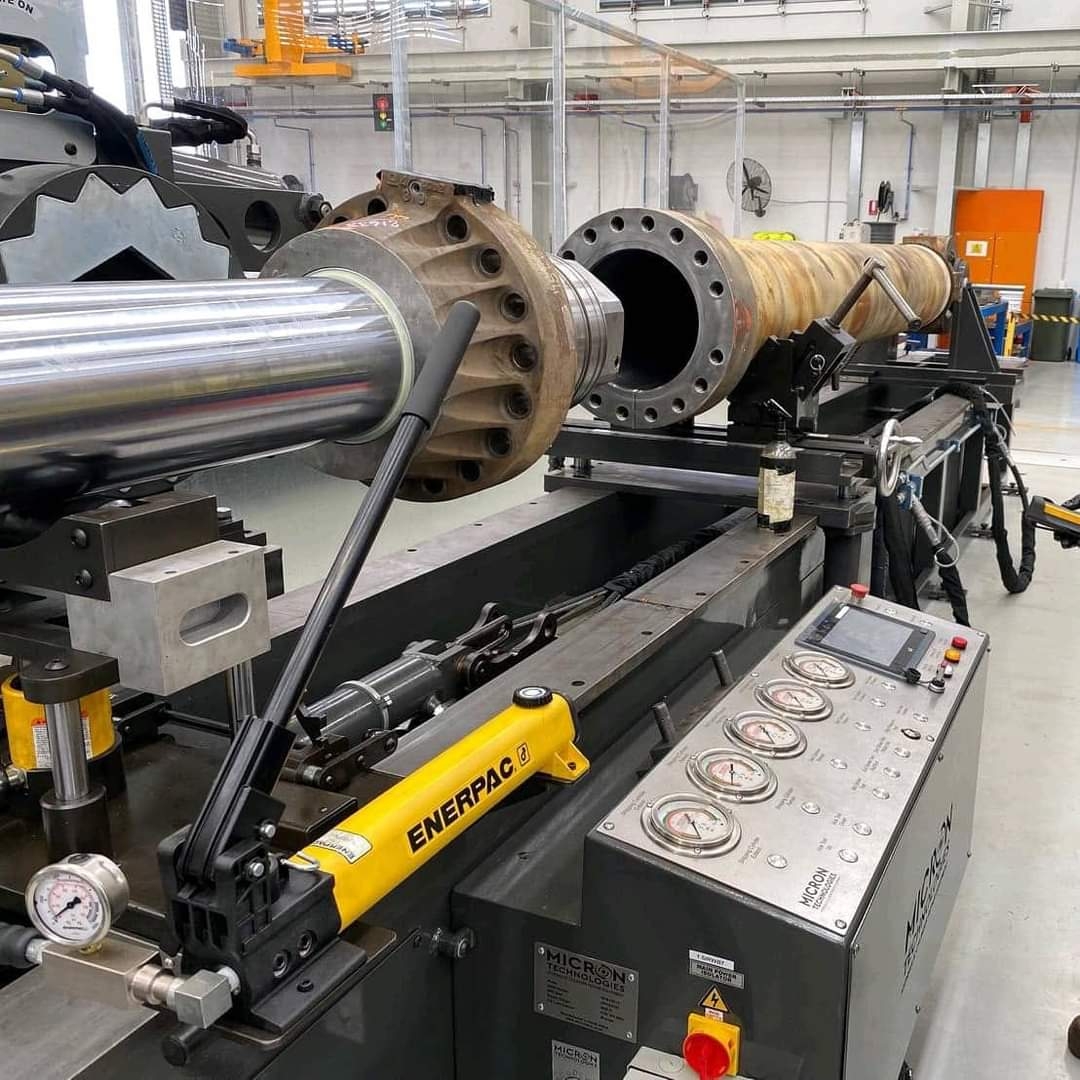

PRESSURE TEST AND LEAKAGE CONTROL

Testing: Each assembled cylinder is subjected to a 100% pressure and tightness test. Testing parameters: 1. Pressure test 2. Internal leakage test 3. Life cycle test

SHIPMENT AND PACKAGING

Packaging is carried out in accordance with local and international regulations (ISPM 15) and customer specifications.